Marine electronic production process

We develop reliable, high-performance marine electronics, engineered in Germany.

Combining advanced production facilities, internationally recognized certifications, and decades of engineering experience, we deliver standard and customized marine electronics solutions at our headquarters in Germany, Rottweil. Each product undergoes multiple quality testing, at least four times, meeting the highest quality and safety requirements of the marine industry.

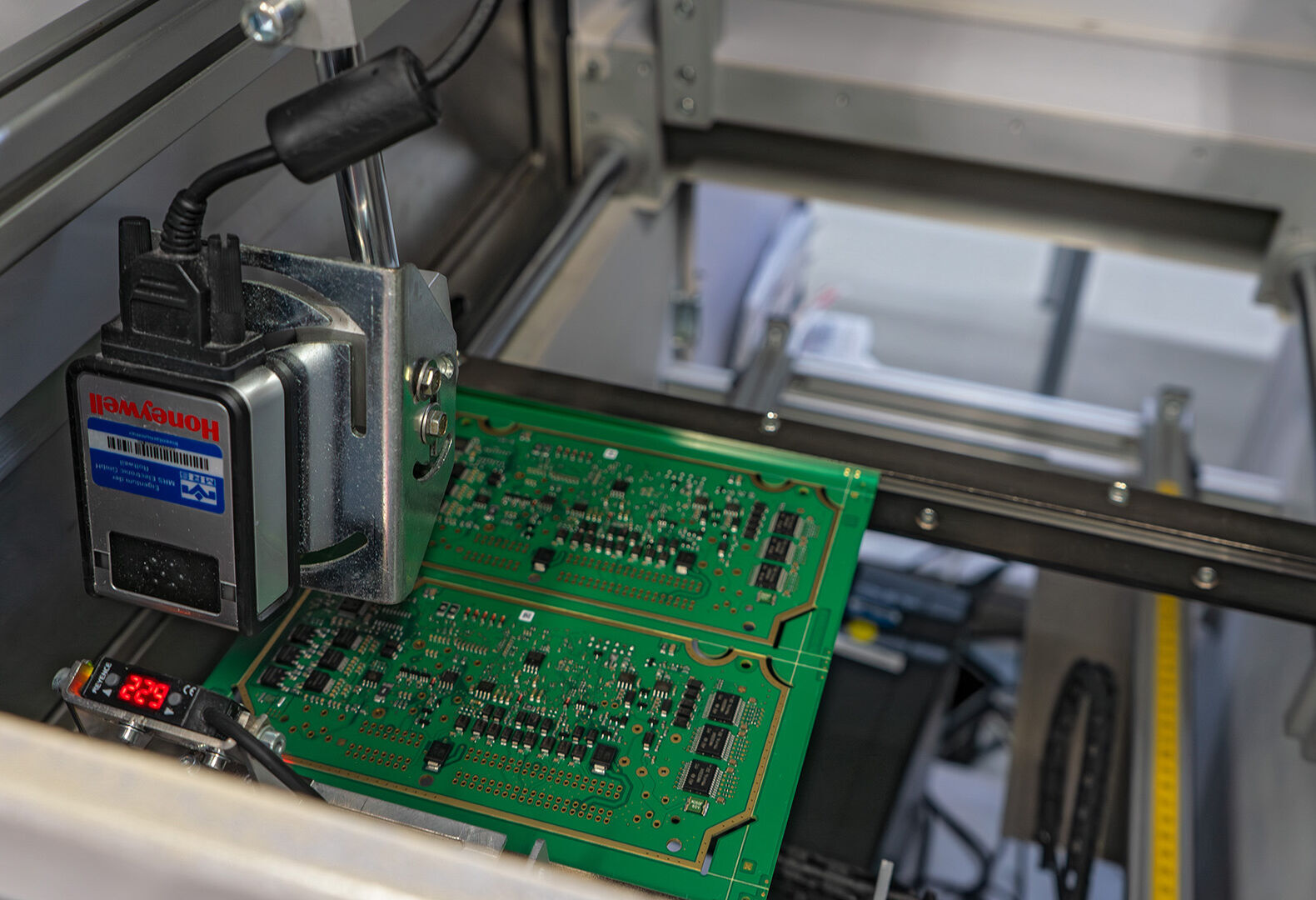

Step 1: Product labeling station

For marine products, reliable traceability starts with the careful selection and procurement of components. To ensure full transparency, at an early stage we are affixing a label to the PCB. All subsequent manufacturing and testing steps are digitally recorded, allowing complete traceability at any time.

Step 2: Surface-Mount Device (SMD)

In our SMD production line, PCB assembly begins with the application of solder paste using a precise printing process. The quality of the solder paste deposition is verified through solder paste inspection (SPI). The boards are then fitted with components such as resistors, capacitors, and processors, followed by soldering in a controlled reflow oven.

Step 3: AOI

Following the SMD process, both the components and soldering results are inspected using Automatic Optical Inspection (AOI).

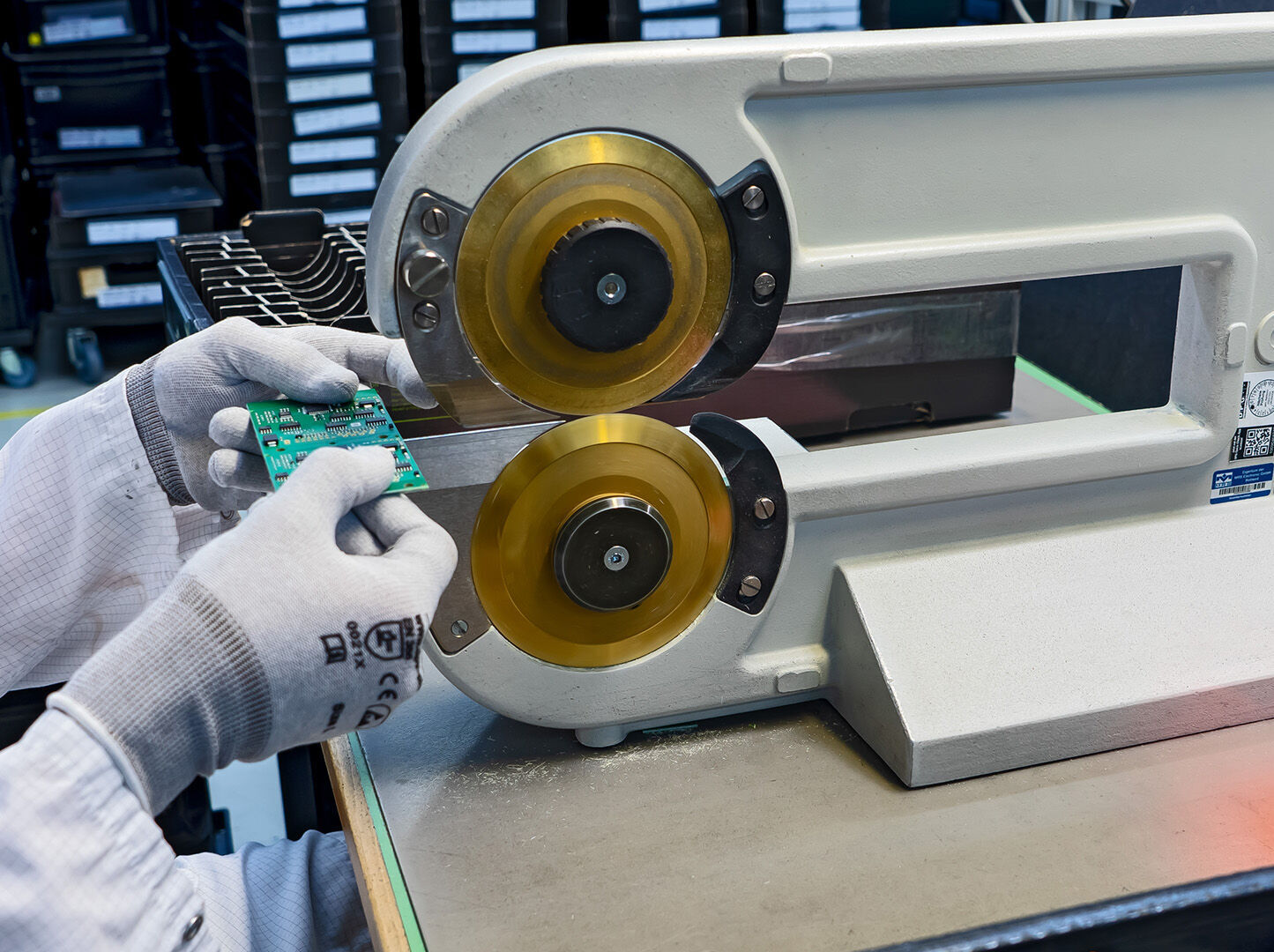

Step 4: Depaneling

To separate individual PCBs from the panel, we use processes such as roller cutting or CNC milling, depending on the specific design and requirements.

Step 5: Manual Assembly

Components such as connectors, relays, and displays that cannot be placed during the SMD process are manually installed onto the individual circuit boards.

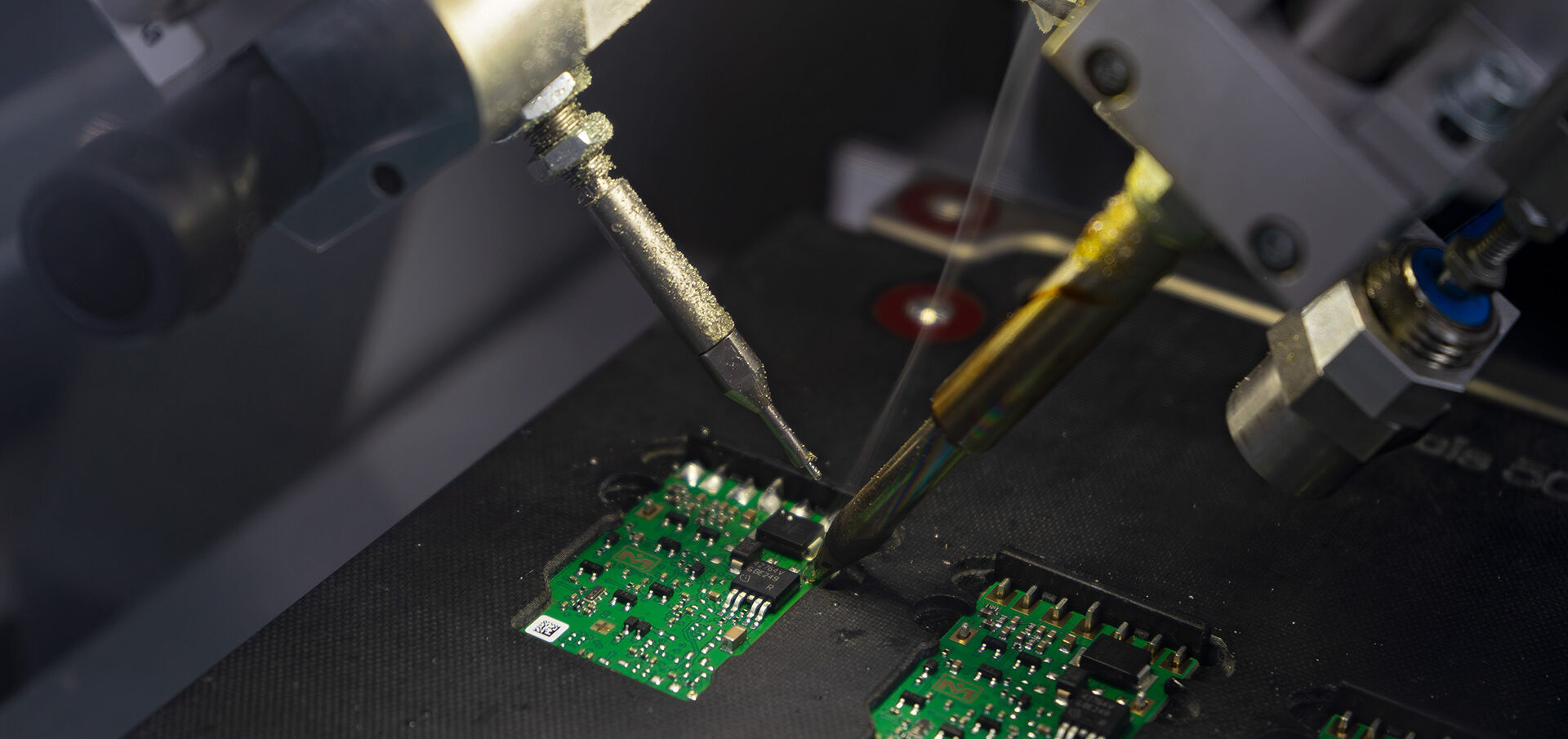

Step 6: Soldering

The manually installed connectors are soldered to the PCB using wave soldering, selective soldering, or robotic soldering processes. The appropriate soldering method is selected based on PCB component density and the precision required to ensure reliable performance.

Step 7: Potting / Coating

Depending on the required level of environmental protection, the module is either fully potted or coated. The applied potting compound or protective coating safeguards the electronics against moisture, corrosion, and dust, while also enhancing mechanical strength, thermal stability, and electrical insulation.

Step 8: ICT/EOL

Electrical functional testing is performed both before and after potting or coating to verify the assemblies. This includes testing of the PCB as well as the fully assembled product. Once all specified requirements are fulfilled, the module is parameterized, and the software is programmed onto the module.

Step 9: Printing

The finished product is marked using pad printing or, in exceptional cases, with an applied label. Customers can choose between a customized design or the standard MRS marking.

Step 10: Storage/Shipping

The completed modules are either shipped directly to our customers or stored in our warehouse until delivery.